Mochini oa ho betla ka Tube

Kakaretso e hlalosang

Letoto lena la mochini oa ho kenya ka lebokose o iketsang o nang le mesebetsi e mengata, o kopantsoeng le theknoloji e tsoetseng pele lapeng le kantle ho naha bakeng sa ho kopanya le ho ntlafatsa, o na le litšobotsi tsa ts'ebetso e tsitsitseng, tlhahiso e phahameng, tšebeliso e tlase ea matla, ts'ebetso e bonolo, ponahalo e ntle, boleng bo botle le boemo bo phahameng ba othomathike. E sebelisoa meriana e mengata, lijo, lik'hemik'hale tsa letsatsi le letsatsi, lisebelisoa tsa hardware le tsa motlakase, likarolo tsa likoloi, polasetiki, boithabiso, pampiri ea ntlo le liindasteri tse ling lapeng le kantle ho naha, 'me e tsejoa haholo ebile e hlomphuoa ke basebelisi.

Likaroloana

1. E amohela mokhoa oa ho paka oa ho fepa ka boiketsetso, ho bula mabokose, ho kenya mabokose, ho hatisa linomoro tsa sehlopha, ho tiisa mabokose le ho tlosa litšila, ka sebopeho se senyenyane le se utloahalang le ts'ebetso le tokiso e bonolo;

2. Ka ho sebedisa servo/stepping motor, touch screen le PLC programmable control system, tshebetso ya pontsho ya sebopeho sa motho le mochini e hlakile ebile e bonolo, tekanyo ya othomathike e phahame, mme e fetotswe botho haholoanyane;

3. Sistimi ea ho lemoha le ho latela ea photoelectric eye e sebelisoa ka bo eona, e le hore sephutheloana se se nang letho se se ke sa kenngoa ka lebokoseng, 'me thepa ea ho paka e bolokoe ka hohle kamoo ho ka khonehang;

4. Mefuta e mengata ea liphutheloana, phetoho e bonolo, litlhaloso le boholo bo fapaneng li ka fihlella phetoho e potlakileng;

5. Ha ho hlokahale ho fetola hlobo ho fetola tlhaloso, empa ho hlokahala feela ho e lokisa;

6. Sesebelisoa sa tšireletso ea ho emisa ka boiketsetso le ho khanna ka motlakase se sebelisoa ha thepa e se sebakeng sa eona, e leng se sireletsehileng le se tšepahalang haholoanyane;

7. Ho latela ditlhoko tsa bareki, re ka sebedisa sekoahelo sa polokeho se phethotsweng, se bonolo ho se sebedisa le se shebahalang se le setle.

8. E ka phethahatsa tlhahiso ea khokahano ka mochini oa polasetiki oa aluminium, mochini oa ho paka mosamo, mochini oa ho paka oa mahlakore a mararo, mohala oa botlolo, mochini oa ho tlatsa, mochini oa ho ngola mabitso, printa ea inkjet, sesebelisoa sa ho lekanya sa inthanete, mela e meng ea tlhahiso, jj;

9. Mefuta eohle ea sistimi ea ho fepa ka boiketsetso le ea ho fepa ka mabokose e ka etsoa ho latela litlhoko tsa ho paka;

10. Mochini oa sekhomaretsi se chesang o ka khethoa ho latela litlhoko tsa bareki. Ho fafatsa sekhomaretsi se chesang le ho borashe ka mechine ho ka sebelisoa ho koala lebokose.

Tlhaloso e ka Sehloohong

| Mohlala | TW-120C | |

| NTHO | Lintlha | TLHAHLOBO |

| Smoroto/bokgoni | 50-100Carton/motsotso |

|

| Mtekanyo ea lehloa | 3100×1250×1950 | (L)×(W)×(H) |

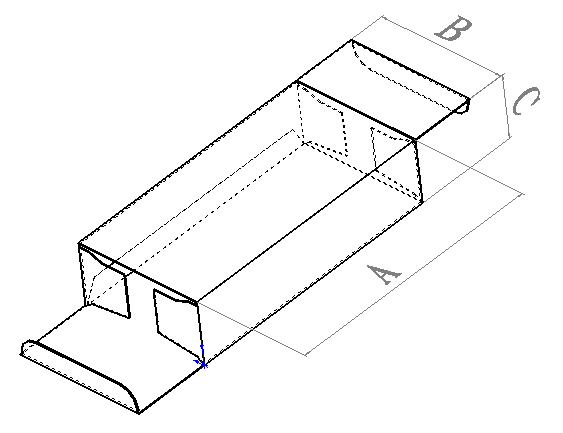

| Cmefuta e fapaneng ea boholo ba arton | Bonyane.65×20×14mm bonyane 65×20×14mm | A×B×C |

| Boholo.200×80×70mm boholo ba 200×80×70mm | A×B×C | |

| Ckopo ea thepa ea arton | Wkhateboto e betliloeng 250-350g/m2 Gkarete ea mahlaseli 300-400g/m2 |

|

| Ckhatello ea moea e hatelletsoeng/tšebeliso ea moea | ≥0.6Mpa/≤0.3m3 motsotso |

|

| Mphofo ea ain | 1.5KW |

|

| Sehloohomatla a enjene | 1.5KW |

|

| Mboima ba 'mele bo boima | 1500Kg | |

Tlhokomeliso: lihlahisoa tsa k'hamphani ea rona li ntlafatsoa kapele. Haeba ho na le phetoho efe kapa efe, ka kopo sheba lihlahisoa tsa 'nete ntle le tsebiso e 'ngoe!

Kakaretso ea theknoloji ea mohala oa tlhahiso

Mochini oohle o ka etsoa le ho etsoa ho latela maemo a hona joale a GMP.

2. Libaka tse sebetsang tsa mochini oohle lia aroloa, 'me leihlo la photoelectric le tsoang kantle ho naha le sebelisoa ho latela le ho lemoha mochini ka bohona.

3、Ha sehlahisoa se kenngwa ka boiketsetso ka hara setshwari sa polasetiki, se ka etsa hore ho tlatswe le ho kwalwa ha lebokose ka boiketsetso ka botlalo.

4. Ketso ea sebaka se seng le se seng sa ho sebetsa sa mochini oohle e na le khokahano e phahameng haholo ea othomathiki ea elektroniki, e leng se etsang hore ts'ebetso ea mochini e tsamaisane haholoanyane, e leka-lekane haholoanyane le lerata le tlase.

5. Mochini o bonolo ho o sebetsa, taolo e ka hlophisoang ea PLC, sebopeho sa mochini oa ho ama oa motho

6, Sebopeho sa tlhahiso sa sistimi ea taolo ea othomathiki ea PLC ea mochini se ka hlokomela tlhokomelo ea nako ea sebele ea lisebelisoa tsa ho paka tse ka morao.

7.Boemo bo phahameng ba othomathike, mefuta e mengata ea taolo, ho nepahala ha taolo e phahameng, karabelo ea taolo e bonolo le botsitso bo botle.

8.Palo ea likarolo e nyane, sebopeho sa mochini se bonolo, 'me tlhokomelo e bonolo.

9. Moralo o tlase oa DB oa mochini (lerata la lisebelisoa le ka tlase ho 75 dB).

10, Lebelo le phahameng ka ho fetisisa la tlhahiso la mohala ona ke mabokose a 100 / min, 'me lebelo le tsitsitseng la tlhahiso ke mabokose a 30-100 / min.

11, Mohala oohle oa leoto o amohela poleiti ea leoto la screw, 'me bophahamo bo ka fetoloa.

Mohlala

Video

Lihlopha tsa lihlahisoa

Lengolo la rona la Litaba la Beke le Beke

Ke 'nete e thehiloeng khale hore molopolli o tla khotsofala ke

leqephe le baloang habonolo ha le shebile.

-

Imeile

-

Mohala

-

WhatsApp

-

Holimo