Tharollo ea Pharmaceutical Blister Packaging For Tablets le Capsules

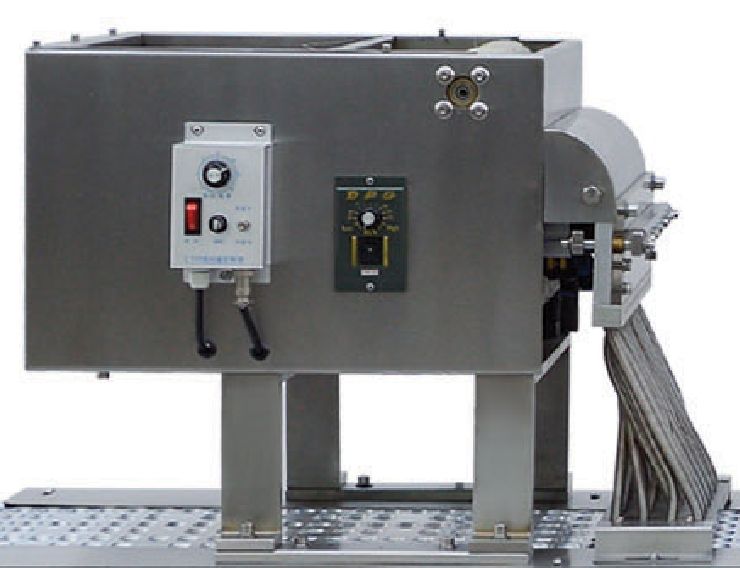

Likaroloana

1. Mochini oohle o ka aroloa ka liphutheloana ho kenya lifti ea limithara tse 2.2 le workshop ea ho hloekisa e arohaneng.

2. Likarolo tsa bohlokoa kaofela li entsoe ka tšepe e sa hloekang ea boleng bo phahameng le lisebelisoa tse phahameng tsa aluminium alloy.

3. Sesebelisoa sa ho beha hlobo sa Novel, Ho bonolo haholo ho nkela hlobo sebaka ka hlobo ea boemo le seporo sa tataiso eohle, ho fihlela litlhoko tse akaretsang tsa phetoho e potlakileng ea hlobo.

4. Bakeng sa seteishene se ikemetseng etsa indentation le karohano ea nomoro ea batch, e le ho netefatsa ho hlaka ha indentation le khatiso (indentation le batch number e ka boela ea e-ba boemong).

5. Ho fetisoa ha mochine ho arohane le sebaka sa mosebetsi ho thibela tšilafalo le ho nolofatsa ho hloekisa.

6. Ho fepa ka lintho tse bonahalang ho laoloa ke mochine o nepahetseng oa servo, ho nepahala ha synchronous le bolelele ba stroke li behiloe ka mokhoa o sa reroang ke mochine oa mochine oa motho.

7. Mokelikeli oa ho tiisa mocheso o behoa tlas'a seteishene sa ho tiisa mocheso ho fokotsa setsi sa mochine, ho matlafatsa botsitso ba ho sebetsa ha thepa.Bakeng sa sebaka le mochine oa phetisetso o arohane ka ho feletseng ho thibela tšilafalo, ho bonolo ho hloekisa.

8. Aluminium / polasetiki (ho chesa ho etsa) le aluminium / aluminium (ho etsa serame) Mekhatlo e Akaretsang: Aluminium / Aluminium packing e fetola feela hlobo le phepelo e tsamaisanang le eona e OK.

Kopo

Tšobotsi e kholo ka ho fetisisa ea thepa ena ke ho sebelisa sebopeho sa sebopeho sa hlobo, se loketseng bareki ho nkela hlobo sebaka, ho fokotsa nako ea ho lokisa liphoso le litšenyehelo tsa thepa, likarolo tsa bohlokoa li entsoe ka tšepe e sa hloekang le lisebelisoa tsa boleng bo phahameng ba Aluminium Alloy ka setsi sa machining (CNC), ho itšeha ka seipone le lisebelisoa tse ling tse nepahetseng tsa CNC ho mofuta o le mong oa ho sebetsa, ho boloka sebopeho sa pele, ho totobatsa boleng bo botle. Sekoaelo se sireletsang pepeneneng sa mahlale a matle ho netefatsa polokeho le ts'ebetso ea ts'ebetso ea sekoaelo sa tšepe e sa hloekang se eketsa setaele se se nang moeli bakeng sa moralo o akaretsang, lihlahisoa tsa mochini le tsona li ka thunya botle ba bonono, ts'ebetso eohle ea lintlha tsa ho lelekisa mohopolo oa phetheho ho pholletsa le moralo le tlhahiso.

Litlhaloso

| Mohlala | DPP88 | DPP140 | DPP250 | DPP350 | |

| Khafetsa ea ho itšeha (ho itšeha/motsotso) (boholo bo loketseng: 80 * 57mm) | 10-30 | 15-45 | 15-45 | 15-45 | |

| Max. Sebaka sa ho Etsa le Botebo(mm) | 100*90*15 | 140*110*15 | 250*120*15 | 350*130*15 | |

| Sebaka se Fetohang sa Maeto(mm) | 40-100 | 30-120 | 30-130 | 30-140 | |

| Lintho tsa ho paka (IDΦ75) | PVC(mm) | (0.15-0.4)*110*(Φ300) | (0.15-0.4)×160×(Φ350) | (0.15-0.4)×260×(Φ400) | (0.15-0.6)×350×(Φ400) |

| PTP(mm) | (0.02-0.15)*110*(Φ250) | (0.02-0.15)×160×(Φ350) | (0.02-0.15)×260×(Φ400) | (0.02-0.15)×350×(Φ400) | |

| Palo ea li-volts | 220V/1P 50Hz | 380V/3P 50Hz | 380V/3P 50Hz | 380V/3P 50Hz | |

| Matla(kw) | 4.5 | 5.5 | 8 | 9.5 | |

| Khatello ea moea (e itokisitse) | 0.6-0.8Mpa ³0.3m3/min | 0.6-0.8Mpa≥0.4m³/min | 0.6-0.8Mpa≥0.45m³/min | 0.6-0.8Mpa≥0.6m³/min | |

| Tšebeliso ea metsi hape kapa a potolohang metsi (L/h) | 30-50 | 40-80 | 40-80 | 60-100 | |

| Kakaretso Dimension (L*W*H)(mm) | 1700*450*1100 | 2400*650*1450 | 2900*750*1600 | 3650*850*1700 | |

| Boima (kg) | 300 | 800 | 1200 | 2000 | |

Lihlopha tsa lihlahisoa

Sengoliloeng sa Rōna sa Beke le Beke

Ke taba ea nako e telele e tiisitsoeng eo morekisi a tla khotsofatsoa ke eona

e balehang leqepheng ha o sheba.

-

E-mail

-

Mohala

-

Whatsapp

-

Holimo